In the relentless pursuit of unparalleled purity across myriad industrial processes, the role of ion exchange resin stands paramount, representing a cornerstone technology for water treatment, chemical processing, and beyond. This sophisticated polymer material facilitates the reversible interchange of ions between a solid phase (the resin) and a liquid phase (the solution), enabling precise control over solution composition. The global market for these resins continues its robust expansion, driven by escalating demands for clean water, stringent environmental regulations, and the burgeoning needs of industries such as power generation, pharmaceuticals, and electronics. The versatility of ion exchange resins lies in their ability to selectively remove undesirable ions, recover valuable resources, and demineralize water to ultra-pure standards, making them indispensable. As industries evolve, so too does the complexity of their water and process stream requirements, necessitating high-performance solutions like strong base anion exchange resins to tackle challenging contaminants and ensure operational efficiency. The continuous innovation in resin chemistry, structural integrity, and application-specific formulations is what propels this sector forward, promising even more specialized and efficient solutions for the intricate separation challenges of tomorrow, underscoring their critical contribution to sustainable industrial practices and environmental stewardship worldwide.

Within the broad spectrum of ion exchange technologies, the distinction between cation and anion exchange resin is fundamental, each designed to target specific types of ionic contaminants. Anion exchange resins, specifically, are engineered to capture negatively charged ions, playing a crucial role in processes like dealkalization, nitrate removal, and demineralization where they work in tandem with cation exchange resins. For instance, Strong Base Anion Exchange Resins, exemplified by products like Strong Base Anion Exchange Resin 201X8, exhibit robust performance across a wide pH range, offering exceptional operational capacity and chemical stability. Their utility extends from softening industrial water to polishing condensate in power plants and purifying chemical intermediates. This enduring performance is a testament to meticulous manufacturing processes and stringent quality control measures, ensuring that each batch of resin meets demanding industry specifications. The advancements in resin manufacturing, including optimized bead size distribution and enhanced cross-linking, further contribute to improved kinetics, greater resistance to fouling, and prolonged service life. This continuous refinement in resin technology addresses the growing industrial imperative for highly efficient, cost-effective, and environmentally compliant water and process stream management solutions, cementing the irreplaceable position of these specialized materials in modern industrial ecosystems.

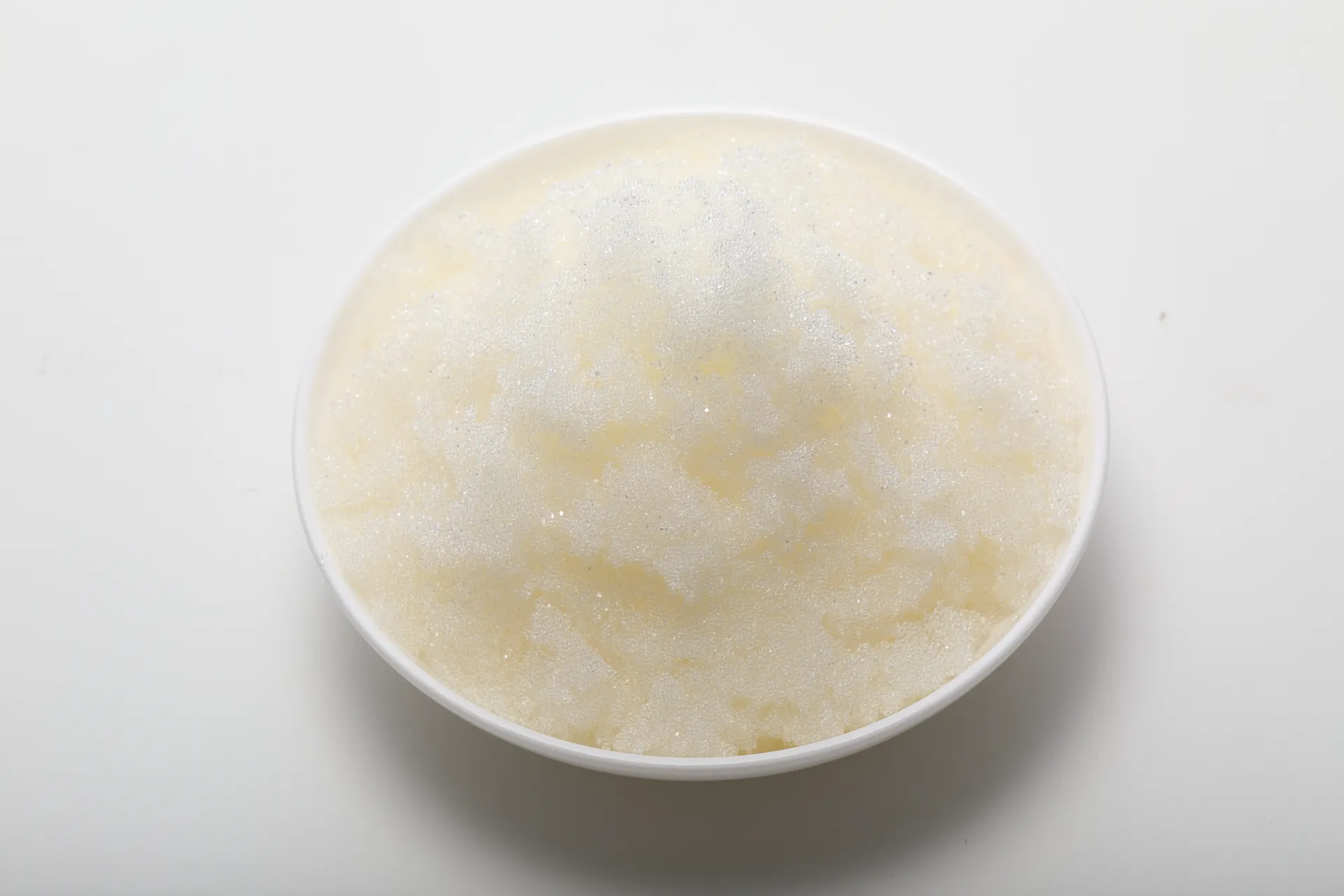

The production of high-quality ion exchange resin is a complex, multi-stage manufacturing process that combines advanced chemical engineering with precise control systems to ensure product consistency and performance. It typically begins with the polymerization of monomers, such as styrene and divinylbenzene, to form a porous polymer matrix, often in the form of spherical beads. This base material dictates the mechanical strength and pore structure of the final resin. Following polymerization, the beads undergo a series of chemical modifications, known as functionalization. For Strong Base Anion Exchange Resin 201X8, this involves the introduction of quaternary ammonium functional groups onto the polymer matrix, which are responsible for the resin's anion exchange capabilities. The degree of cross-linking, controlled by the amount of divinylbenzene, is critical as it influences the resin's selectivity, capacity, and mechanical stability. A higher degree of cross-linking generally results in a more robust resin with better resistance to osmotic shock and oxidative degradation, albeit with potentially slower kinetics. The meticulous control over these parameters ensures the final product delivers optimal performance in diverse industrial applications.

Quality control is integrated at every phase of the manufacturing process, adhering to international standards such as ISO 9001 and ANSI/AWWA B604 for water treatment resins. This rigorous oversight encompasses raw material inspection, in-process analytical checks for functional group density and bead size distribution, and final product testing for parameters like total exchange capacity, moisture content, effective size, and uniformity coefficient. For example, the lifecycle of a typical ion exchange resin, depending on application and regeneration frequency, can span from 3 to 10 years, highlighting the importance of durable manufacturing. These resins find extensive application across various industries, including petrochemicals for process water treatment and effluent polishing, metallurgy for metal recovery and wastewater purification, and crucial roles in municipal water and wastewater treatment, where they contribute to providing safe drinking water and ensuring responsible discharge. The inherent advantages of using such precisely engineered resins in these sectors include significant energy savings through efficient water reuse, superior corrosion protection for critical infrastructure by removing corrosive ions, and enhanced product quality for the end-user. The ability to customize resin properties for specific industrial challenges, such as high-temperature resistance or selective contaminant removal, further solidifies their essential role in modern industrial operations, offering tailored solutions that optimize process efficiency and environmental compliance.

The Strong Base Anion Exchange Resin 201X8 is a premium Type I macro-porous strong base anion exchange resin, specifically designed for applications requiring high operational capacity, excellent chemical stability, and superior resistance to organic fouling. Its macro-porous structure provides a larger surface area for ion exchange kinetics, making it highly effective for treating water streams with high organic content or for applications where rapid kinetics are essential. This resin typically boasts a total exchange capacity ranging from 1.2 to 1.4 meq/mL (milliequivalents per milliliter) wet volume, indicating its high efficiency in removing anions. The moisture retention, usually between 45% and 55%, reflects its cross-linking degree and structural integrity, crucial for mechanical stability and longevity. The bead size distribution is meticulously controlled, with an effective size typically between 0.60 to 0.80 mm and a uniformity coefficient below 1.6, ensuring optimal hydraulic performance, minimal pressure drop, and consistent bed expansion during backwash and regeneration cycles. These precise physical characteristics are vital for reliable and efficient operation in large-scale industrial systems.

| Parameter | Typical Value/Range | Unit |

|---|---|---|

| Resin Type | Strong Base Anion, Type I (Macroporous) | N/A |

| Ionic Form as Shipped | Cl- | N/A |

| Total Exchange Capacity | 1.2 - 1.4 | meq/mL |

| Moisture Retention | 45 - 55 | % |

| Effective Size | 0.60 - 0.80 | mm |

| Uniformity Coefficient | ≤ 1.6 | N/A |

| Density (Wet, Cl- form) | 1.05 - 1.08 | g/mL |

| pH Range | 0 - 14 | N/A |

| Max. Operating Temperature | 100 (Cl- form) | °C |

Compared to conventional gel-type resins or even some specific dowex exchange resin variants, the macroporous structure of 201X8 offers enhanced resistance to fouling by larger organic molecules, which can blind the functional sites of gel-type resins and reduce their operational capacity. This resilience is particularly beneficial in applications involving complex feedwaters. Its excellent thermal and chemical stability ensures long service life, even under harsh operating conditions, including high temperatures and aggressive chemical environments often encountered in industrial demineralization trains. The high regeneration efficiency of Strong Base Anion Exchange Resin 201X8 translates into reduced consumption of regenerant chemicals (typically caustic soda), leading to lower operational costs and less waste generation. Furthermore, its robust physical characteristics minimize bead breakage and pressure drop, contributing to stable and predictable system performance over extended periods. These technical attributes collectively make Strong Base Anion Exchange Resin 201X8 a superior choice for industries demanding reliable and high-performance anion removal solutions, ensuring consistent water quality and process integrity.

The robust capabilities of Strong Base Anion Exchange Resin 201X8 enable its deployment across a multitude of critical industrial applications, addressing diverse water and process treatment challenges. A primary application is in comprehensive demineralization systems, often used in conjunction with strong acid cation exchange resins, to produce ultra-pure water for power generation (boiler feed water), semiconductor manufacturing, and pharmaceutical production, where even trace levels of ionic impurities can severely compromise product quality or damage sensitive equipment. Another significant area is the removal of specific anionic contaminants such as nitrates, sulfates, and chlorides from potable water supplies, ensuring compliance with stringent public health standards. Furthermore, it plays a vital role in industrial wastewater treatment, facilitating the removal of heavy metals as anionic complexes or harmful organic acids, thus helping industries meet discharge regulations and promoting environmental responsibility. Its resistance to fouling makes it particularly adept at treating complex industrial effluents that might contain high levels of dissolved organic matter, where conventional resins might quickly lose efficiency. The resin's stable performance ensures continuous operation and minimizes downtime, which is crucial for high-volume industrial processes that cannot afford interruptions, providing a reliable backbone for purity requirements.

Real-world applications underscore the effectiveness of this specific ion exchange resin. For instance, in a large-scale power plant, the Strong Base Anion Exchange Resin 201X8 was implemented as part of the condensate polishing system. The plant experienced issues with silica and chloride ingress into the boiler feed water, leading to turbine corrosion and efficiency losses. By integrating 201X8, the plant achieved consistent boiler water quality with silica levels consistently below 5 ppb and chloride levels below 1 ppb, significantly extending turbine life and reducing maintenance costs by approximately 15% annually. Another compelling case involves a pharmaceutical manufacturer requiring highly purified water for injectable solutions. Their existing system struggled with variable TOC (Total Organic Carbon) and ionic load. By replacing a competitor's resin with 201X8, the manufacturer not only achieved consistent USP (United States Pharmacopeia) purified water standards but also noted a 10% reduction in regenerant chemical consumption due to the resin's higher working capacity and regeneration efficiency. These examples highlight the resin's technical prowess and economic advantages, demonstrating its tangible impact on operational excellence and product integrity across diverse high-stakes industrial environments, cementing its position as a go-to solution for challenging purification tasks and proving its robust capability in real-world scenarios.

In a competitive landscape dominated by established players and emerging innovators, our commitment to pioneering high-performance ion exchange resin solutions sets us apart. Our products, including the Strong Base Anion Exchange Resin 201X8, are not merely commodities but rather the culmination of extensive research, rigorous testing, and decades of accumulated expertise in polymer chemistry and water treatment technologies. While brands like Dowex have set industry benchmarks, our focus is on delivering highly specialized and superior alternatives that meet the evolving demands of modern industries, often surpassing conventional solutions in specific performance metrics. We pride ourselves on offering not just off-the-shelf products, but also highly customized solutions tailored to the unique challenges of each client. This customization involves adjusting resin parameters such as functional group density, cross-linking levels, bead size distribution, and even specific pore structures to optimize performance for unusual contaminants, fluctuating feedwaters, or extreme operating conditions. This bespoke approach ensures that clients receive the most effective and cost-efficient resin for their precise application, maximizing system uptime and minimizing operational expenditures, leading to a long-term partnership built on mutual success.

The technical advantages of Strong Base Anion Exchange Resin 201X8 are multifaceted and translate directly into substantial operational and economic benefits. Its superior macroporous structure provides excellent resistance to organic fouling, a common issue that plagues conventional resins, leading to premature capacity loss and increased regeneration frequency. This inherent resilience means extended resin life, reduced replacement costs, and consistent performance over longer periods. Furthermore, its high regeneration efficiency ensures minimal chemical consumption, contributing to lower operating expenses and a reduced environmental footprint through less waste generation. The resin's exceptional mechanical strength minimizes bead breakage during backwash and regeneration cycles, maintaining bed integrity and preventing channeling, which can lead to inefficient ion exchange. This durability and stability ensure predictable and reliable system performance, reducing unexpected downtime and maintenance needs. Clients benefit from significantly lower total cost of ownership (TCO) due to reduced chemical usage, less frequent resin replacement, and optimized system performance. Our long-standing partnerships with leading industrial players, combined with ISO 9001 and CE certifications, underscore our commitment to quality and reliability, reinforcing our position as a trusted partner in advanced purification technologies. The dedication to continuous improvement ensures that our products remain at the forefront of resin technology, providing cutting-edge solutions for today's and tomorrow's industrial demands.

Building and maintaining client trust is paramount in the B2B sector, especially when dealing with critical process components like ion exchange resin. We address common concerns through clear communication and robust support mechanisms. Our frequently asked questions (FAQ) section, for example, typically covers inquiries regarding resin selection for specific applications, regeneration procedures, troubleshooting common operational issues, and proper handling and storage guidelines to maximize resin lifespan. We understand that efficient project execution hinges on reliable logistics, which is why our standard delivery cycle for Strong Base Anion Exchange Resin 201X8 is meticulously managed. For standard orders, we typically ensure dispatch within 5-7 business days of order confirmation, with expedited options available for urgent requirements, depending on destination and volume. Each shipment is accompanied by a Certificate of Analysis, providing detailed batch-specific performance data and confirming adherence to specified parameters. This transparency in our supply chain and product quality verification instills confidence and allows clients to plan their operations with certainty, minimizing logistical risks and ensuring timely project completion.

Our unwavering commitment to quality is underscored by a comprehensive warranty policy for Strong Base Anion Exchange Resin 201X8, ensuring peace of mind for our customers. We guarantee that our resin products conform to the specifications provided at the time of purchase and are free from manufacturing defects. In the unlikely event of a performance issue related to product quality, our dedicated technical support team is readily available to provide expert guidance, conduct thorough investigations, and offer prompt solutions. This post-sales support extends beyond mere problem-solving; it includes proactive consultation on resin optimization, system design recommendations, and training for operational personnel to ensure maximum efficiency and longevity of the resin. Our global network of technical experts and service professionals ensures that assistance is always within reach, providing round-the-clock support for critical industrial applications. This comprehensive approach to customer service, coupled with our stringent quality control and robust product warranty, exemplifies our dedication to fostering long-term, trustworthy partnerships with our clients, ensuring that their purification needs are met with the highest standards of excellence and reliability.

As industries continue to grapple with escalating demands for water purity, resource recovery, and environmental compliance, the role of advanced ion exchange resin technologies, particularly high-performance strong base anion exchange resins like 201X8, will only grow in importance. These materials are not just chemical commodities; they are sophisticated engineering solutions critical to sustainable industrial growth. Their unique ability to selectively remove diverse ionic species, coupled with their resilience and long service life, positions them as indispensable tools in achieving operational excellence and meeting stringent regulatory requirements across sectors ranging from ultrapure water production for microelectronics to efficient wastewater treatment in heavy industries. The continuous advancements in resin chemistry, including enhanced selectivity, fouling resistance, and regeneration efficiency, promise even more tailored and environmentally friendly solutions in the future. Investing in high-quality ion exchange resins is an investment in process reliability, reduced operational costs, and a commitment to environmental stewardship.